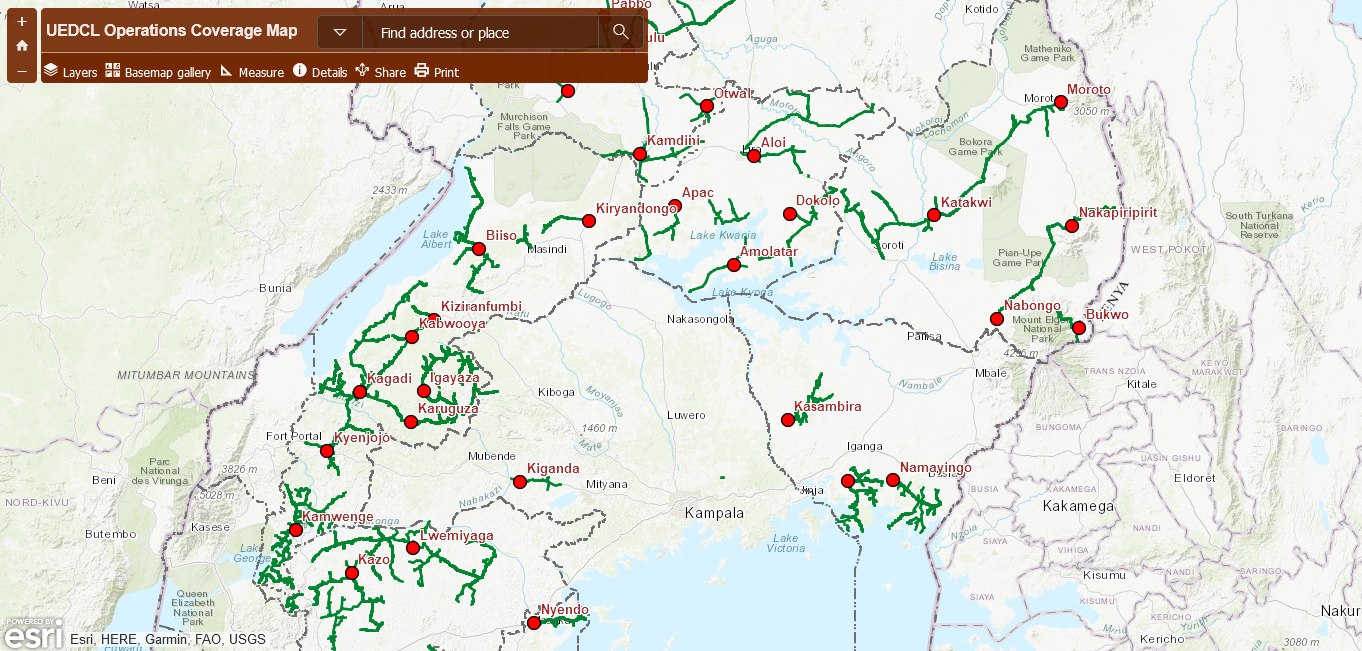

86

Districts Covered

124813

Customers Served

25940

Number of Poles produced annually

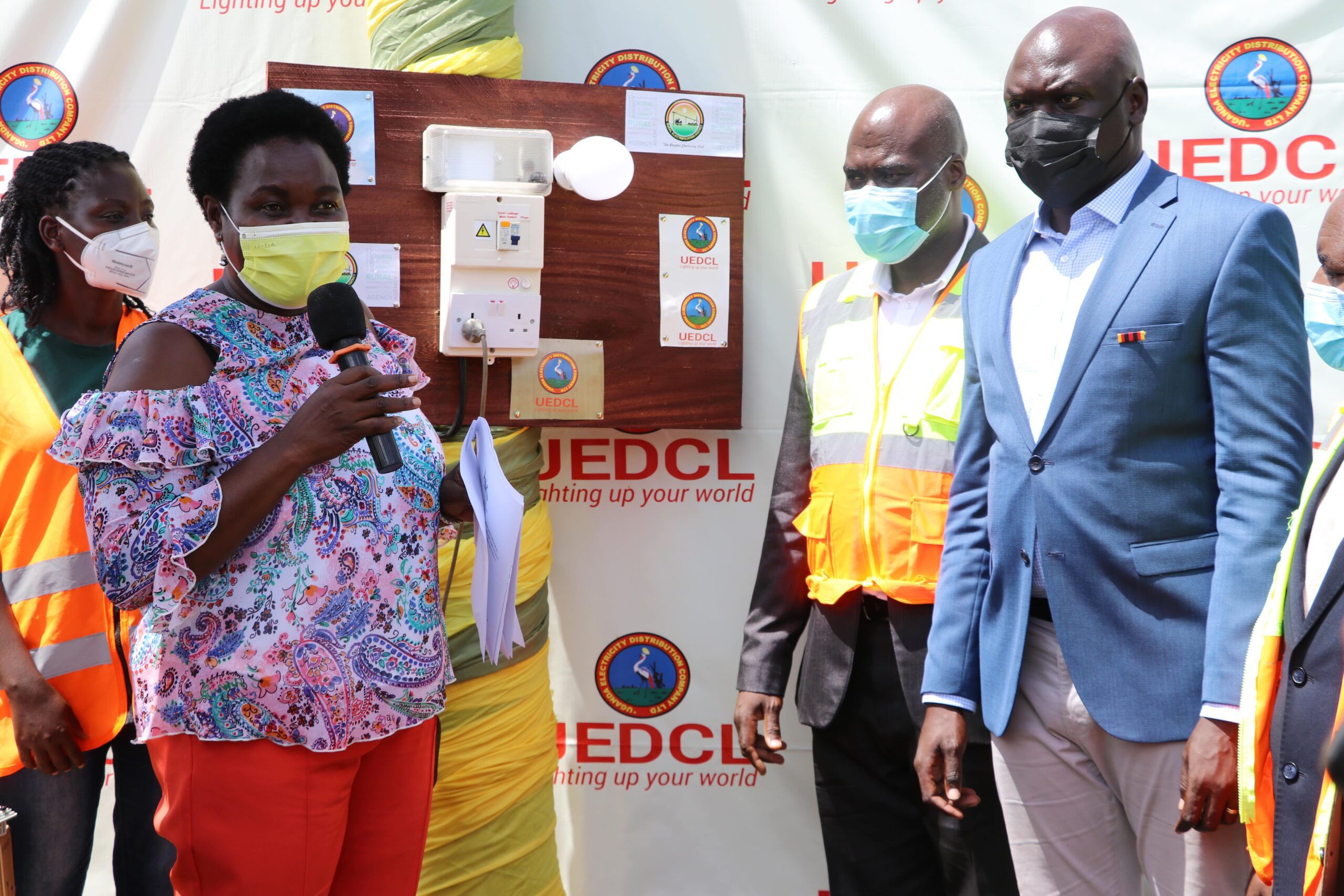

About Uganda Electricity Distribution Company Limited (UEDCL)

Uganda Electricity Distribution Company Limited (UEDCL) was formed in 2001 by the electricity act of 1999 following the split of the Uganda Electricity Board (UEB).

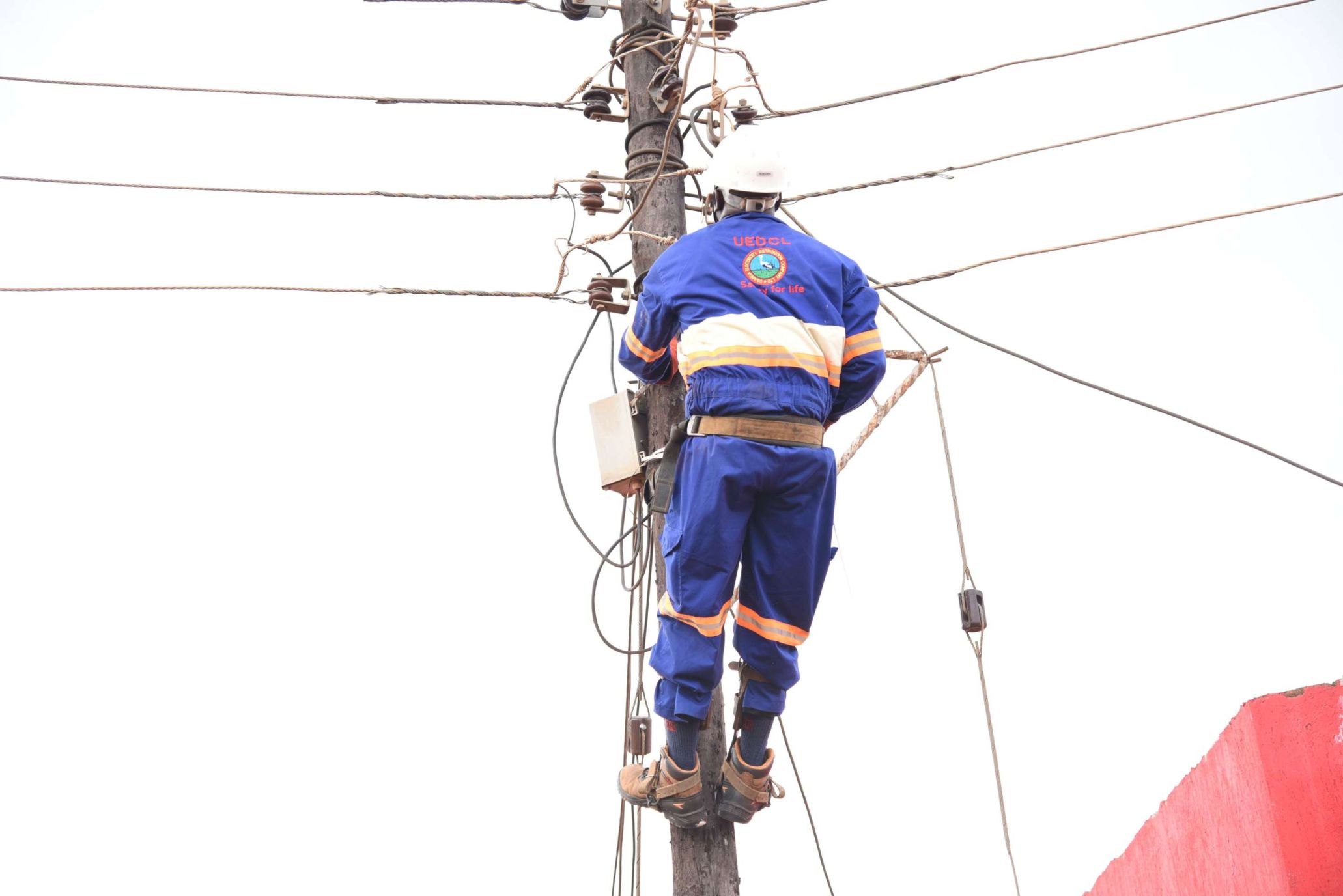

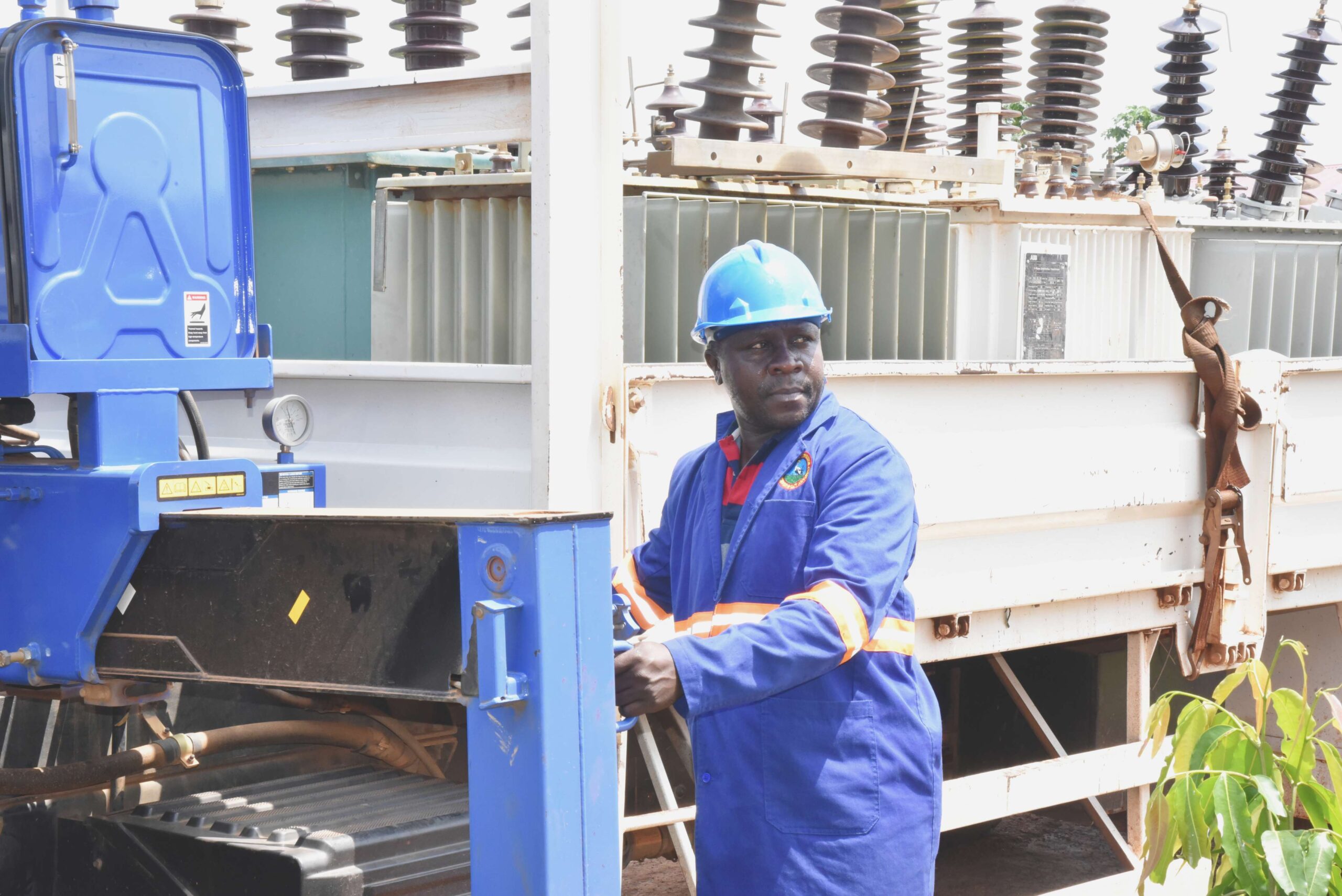

UEDCL’s mandate is to own all the electricity distributions network below 33kv across the country.

News Highlights

UEDCL TOKEN IDENTIFIER (TID) PROJECTS

By Jonan Kiiza The management of Uganda Electricity Distribution Company Limited...

THE ENERGY WEEK AND FORUM 2023 – UEDCL�

By Jonan Kiiza Under the auspices of the Ministry of Energy and Mineral...

UEDCL REQUESTS ERA TO APPROVE 49.9

By Jonan Kiiza The Electricity Regulatory Authority (ERA), in accordance with...

AN ACCOUNT OF POWER NETWORK VANDALIM

By Eng. Protaze Tibyakinura – Chief Engineering and Technical Services...